3D Printing Workshops

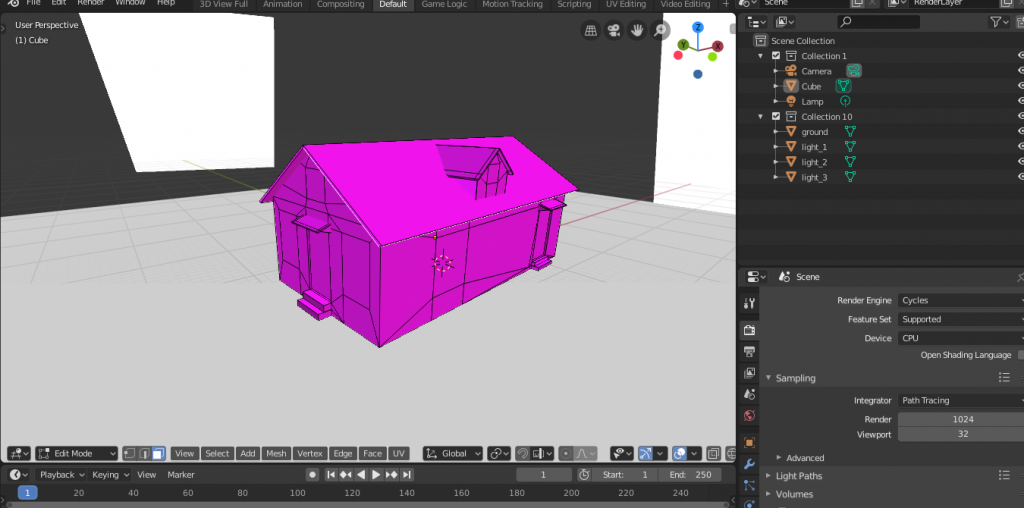

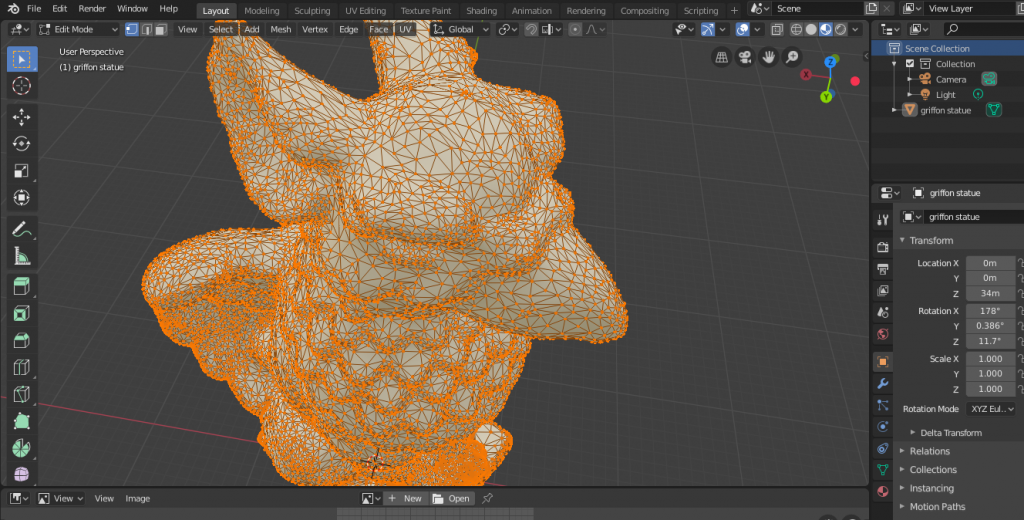

Our workshops are designed to get you on board with the exciting and thrilling technology that 3D printing is.

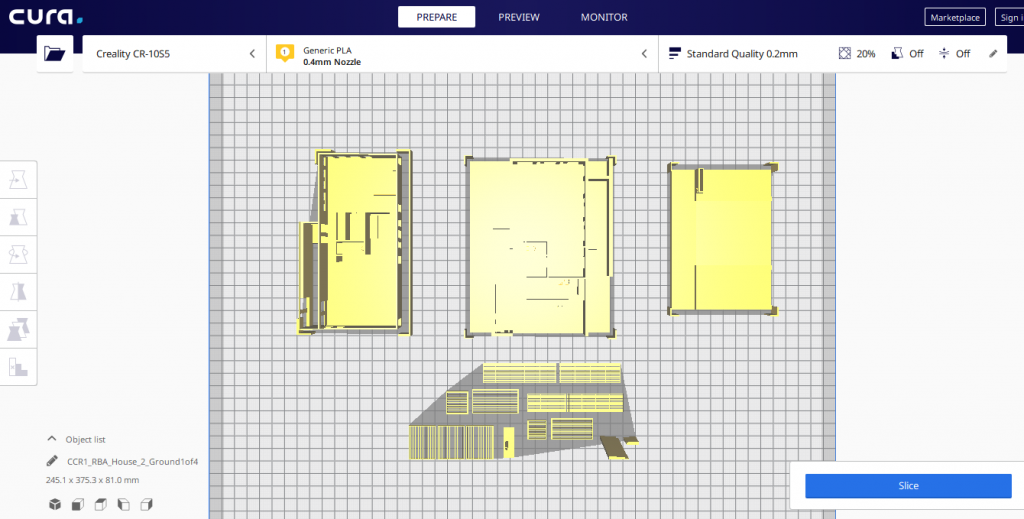

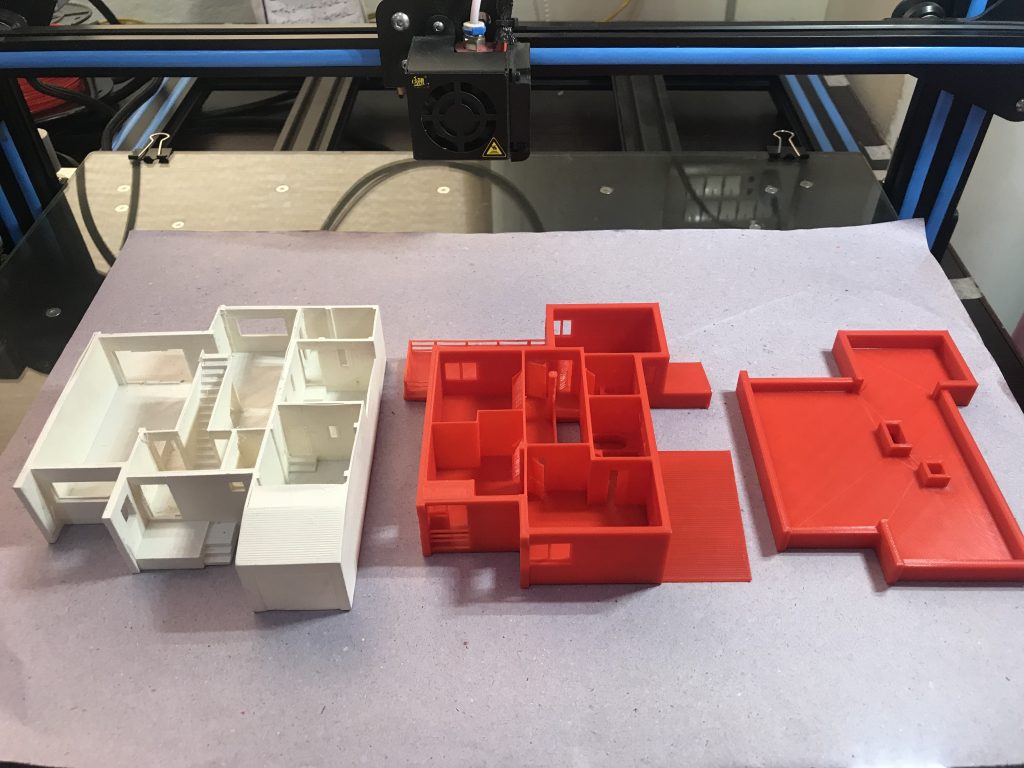

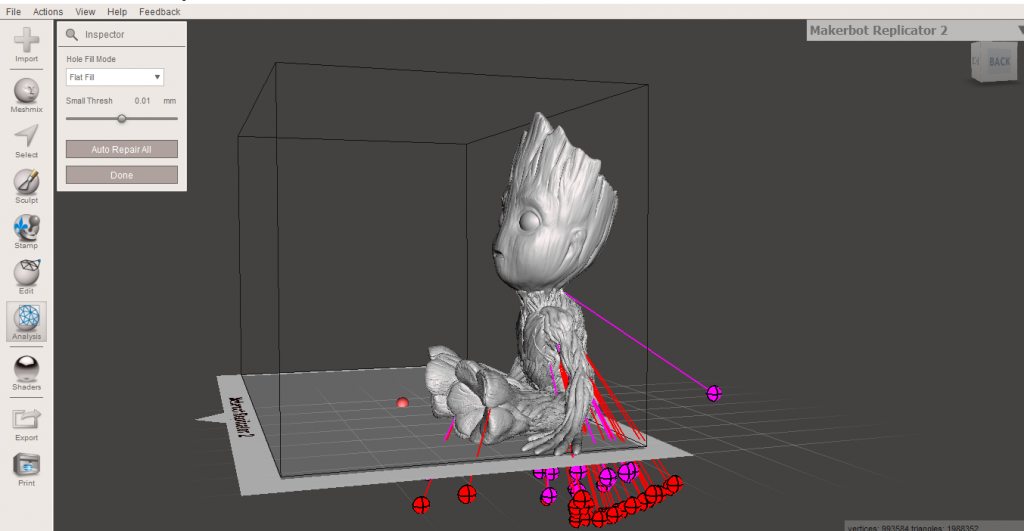

You will learn the basics and working of 3D printer. 3D printers are available on all our workshops so you’ll be able to see its live working and get a better understanding of it. Next we’ll teach you how to slice your models to get it ready for printing and other important settings such as:

- Infill

- Layer height, which establishes the height of each layer of filament in your print

- Retraction settings

- Print Speed

- Bottom/Top thickness

- Shell thickness which refers to number of layers outer wall will have

Our workshops are announced through mail and on website.